Categorizing media defects

This is a response to a prompt over at the TAXIS blog, where we read the first chapter of the classic Geoffrey C. Bowker and Susan Leigh Star, Sorting Things Out: Classification and Its Consequences, (Cambridge, Mass.: MIT Press, 2000).

Media in their broken states can tell us as much about their social construction as they can in their putatively “normal” modes of operation, so I’ve taken an interest in how the designers and manufacturers of CD players and CD media have managed defects in their engineering work. I’ll set aside the question of exactly where or what the “infrastructure” is here—is it the defect-handling electronics? the players? the damaged discs? the entire CD media “ecology”?—for the moment and focus instead on the work of classification in the management of defects in optical media. Most of the sources for the material in this post are journal articles and published reports of research done at various sites over the last 30 or 40 years, with a focus on the CD. I’m drawing on the chosen reading for guidance about how to parse this material as well as where I should look for more.

Emphasizing how categorization is materialized in “stuff”, Bowker and Star note “all classification schemes are a mixture of physical entities, such as paper forms, plugs, or software instructions encoded in silicon” (39). Since we’re doing history and reckoning with the “indeterminacy of the past”, we shouldn’t assume that these schemes are self-consistent: “an institutional memory [presumably of the “work of classification” —EB] can be held simultaneously and with internal contradictions (sometimes piecemeal or distributed and sometimes with entirely different stories at different locations) across a given institutional space.” (41) What I take away from this that historical evidence of categorization will be (1) distributed (a) across media; (b) across time; (c) across (institutional, social, literal) space; and is more likely than not to be (2) inconsistent, meaning that disagreements on the process and outcome of categorizations represented in the archive are not an occasion for resolution or reconciliation on the part of the researcher. Rather, they should be thematized.

That the traces of the work of classification are both distributed and inconsistent seems true for CD defects: the text of technical standards specifies the kinds of defects that the CD system can tolerate, but it is far from the only source for this information, and neither is it exhaustive. For instance, under the heading “Defects”, the IEC standard for the audio CD (IEC 60908, sometimes called the “Red Book”) implies the existence of two major categories of defect: “local” defects and non-local defects (see above). The standard first refers to “random” vs. “burst” errors—properties of a data stream—before it considers how of those errors might be materialized as properties of the physical medium. Thus, from the point of view of the standard, defects are not primarily defined by their physical extent and frequency on the disc but instead by their impact on the detected error rate as the disc is read in a player. For example, a measurement called the block-error rate (BLER), which is proportional to the number of random errors detected by the CIRC decoder, becomes a proxy for the number of non-local defects on the disc, and in turn for the quality of the production process (Pohlmann 1992, 304–306). Similarly, local defects are defined primarily by their effect on the decoder and not by their physical characteristics or their cause. The standard then mandates that “local defects shall not induce audible effects”—an empirical criterion giving wiggle room which allows for concealment instead of correction—and only then moves to a categorization of defects based on their physical properties. The standard states the maximum dimension and density for three kinds of local defect: air bubbles, “black spots”, and “black spots without birefringent area”. Black spots are further qualified to include both “dirt enclosures in the substrate” and “‘pin-holes’ in the reflective layer”.

Most of these defects mentioned in the standard are defects due to the manufacturing process, not due to age, use, or mishandling. CDs are submicroscopic media artifacts which require clean-room techniques to manufacture and the early years of CD manufacturing (1982–1984), production processes saw high rejection rates (Pohlmann 1992, 309), one cause of the relatively high cost of CD media. The CD, of course, is also (in)famously resilient to the patina of scratches and dust invariably acquired after purchase: once the two classical afflictions of phonographic records. In 1983, manufacturers made various extravagant claims for the durability and fidelity of the format even when carelessly handled: “‘you can touch the disc surfaces with your fingers,’ ‘you can play Frisbee with them,’ ‘the sound quality is perfect’” (Ranada 1983, 61. Cited in Kelly 2009, 221). (It’s worth noting here that this suggests that claims for/beliefs about the CD system’s tolerance for defects are also distributed across the various protocols and tools for the handling CD collections: folk wisdom about the format, marketing bumpf, and advice and “tweaks” for audiophiles. On the latter, see Perlman 2003) Interestingly, from the point of view of some engineers who had worked on the CD system, the format’s resilience to dust and mishandling was incidental to its ability to cope with errors introduced into discs by less-than-perfect reproduction processes. For example, Philip McGee—one of over a dozen Philips researchers who completed their master’s degrees at TU Eindhoven on topics related to optical media between 1985 and 2000—noted that

[w]hile the advanced error-correction was originally developed in order to ease the unrealistic manufacturing tolerances which would be involved in producing discs completely free of errors, a very welcome side-effect is immunity from most surface scratches and blemishes on the disc. (McGee 1987, 18–19)

And so another implicit categorization of defects unfolds: a distinction between those defects for which CIRC was intended, and those for which it was not. This maps quite closely onto the distinction between manufacturer-caused and user-caused defects (but is not identical to it, since this distinction is drawn with reference to the lifecycle of the CD-as-commodity), but does not entirely correspond to the distinction between “random” and “burst” errors (which is drawn with respect to the response of the CIRC decoder and quantified in the standard), or the three-way distinction between correctable, concealed, and muted defects (which is jointly enforced by the policies encoded in the error-correction and concealment circuits—and, indeed varies from manufacturer to manufacturer)

Of course, categorizations are also notable for what they exclude, since what cannot be cannot be categorized cannot be counted, and what cannot counted cannot be made visible. (This is axiomatic for Bowker and Star, I think). The “Red Book” standard doesn’t mention fingerprints, despite the fact that they are perhaps the most common kind of aftersale defect on CDs, closely followed by the scratch—also not mentioned in the standard—and, indeed dirt (“matter out of place”) more generally. However, engineers knew that their players had to be robust to disc damage, and, as the standard only went so far in specifying the precise kinds of defect the medium should withstand, leaving many decisions to the manufacturers as matters of implementation, they had considerable flexibility in developing techniques for defect-resistant players. While standardization ensured that a pristine Red Book-compliant CD would reproduce just as faithfully in any compliant player, manufacturers could differentiate their products on the marketplace by adding new features unspecified in—but not incompatible with—the standard. These features included: new user interfaces for addressing and sequencing track playback (for example, the “shuffle” mode, which was not introduced until some years after the first CD players hit the consumer market), improved resilience to fingerprints, scratches and dust (collectively, if inaccurately: “dirt”), and resistance to external shocks (required by the use of CDs in car audio systems and, ultimately, the portable CD player: Discman).

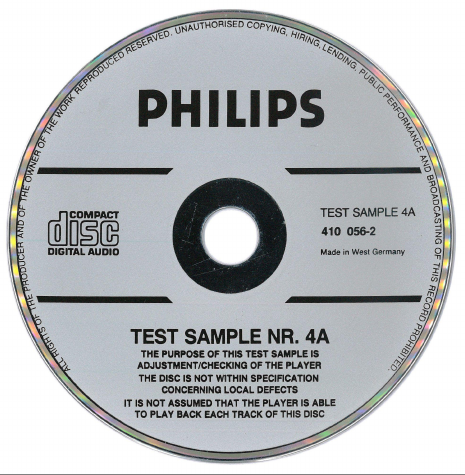

To cope with the latter issues (dirt and external shocks), player manufacturers strove to finesse various error-correcting techniques and design strategies in order to maintain an edge over their competitors. Doing so enabled to them to developing products that were viewed as having what Philips engineers systematically described as greater “playability”. Notably, Philips and Sony maintained libraries of test discs for use by engineers and repair centers which could be used to calibrate and test the performance of their systems. One such disc was the Philips Test Sample 4 (410 079-2, released 1982), which contained a selection of classical (from Handel to Holst) and pop music (Roxy Music, JJ Cale, Elton John &c.) thought to be representative of the kinds of music that early CD owners would take the time to listen to on their expensive players. This disc, then, was designed to put a CD player “through its paces”; it and discs like it were routinely used by audio reviewers in the assessment of CD players for magazines and trade publications, just like test records were and are used today to assess phonograph turntables.

The real power of this disc, however, came when contrasted with its partner, Test Sample 4A (410 056-2, released 1982). 4A contained exactly the same audio content as 4, but with three categories of simulated local defects that had been printed on to the surface of the disc, including: an “interruption in the information layer”, a “black dot at read out side”, and, interestingly, “a simulated fingerprint”. The first two of these were calibrated in size and their positions relative to the start of the relevant track were noted in minutes and seconds. Similar test discs were in use at Sony, while other manufacturers of audio hardware—such as the Japanese company A-BEX/Almedia—made deliberately defective discs available outside of these organisations. Thus, evidence of a categorization scheme in action can also be found literally inscribed on material objects, objects which are used—pragmatically—by engineers in the testing of CD players, and in the creation of schemes for the mitigation of media damage, showing how artifacts and tools themselves constitute Annemarie Mol calls (in a medical but nevertheless apposite context) a “praxiology” of optical media defects. And, crucially, these categorization schemes need not align with those in the related standards, as the case of fingerprint damage suggest. The relationship between standards and categories is not one-to-one (a point that Bowker and Star do make), and it’s worth paying attention—I think—to where artifacts and standards diverge, basically where practices spring up where standards are silent: in the interpretative moment of implementation.

Works cited

Bowker, Geoffrey C., and Susan Leigh Star. Sorting Things Out: Classification and Its Consequences. Inside Technology. Cambridge, Mass.: The MIT Press, 2000.

Kelly, Caleb. Cracked Media: The Sound of Malfunction. Cambridge, Mass.: MIT Press, 2009.

McGee, Philip J. “A Fast Trackloss Recovery Strategy for Compact Disc.” Master thesis, Technische Universiteit Eindhoven, 1987.

Perlman, Marc. “Consuming Audio: An Introduction to Tweak Theory.” Tijdschrift Voor Mediageschiedenis 6, no. 2 (2003): 117–28.

Pohlmann, Ken C. The Compact Disc Handbook. 2nd ed. The Computer Music and Digital Audio Series, v. 5. Madison, WI: A-R Editions, 1992.

Ranada, David. “Hands on the Digital Disc.” Stereo Review, April 1983.